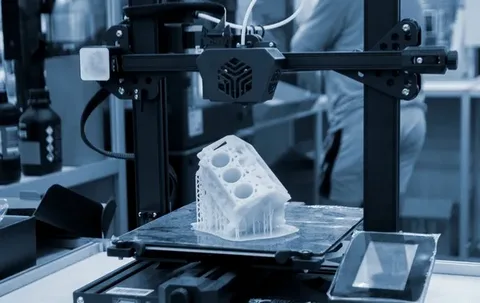

In recent years, the adoption of Plastic 3D Printing Service has transformed how industries approach prototyping, production, and product customization. Traditionally, manufacturing relied on subtractive processes such as machining or injection molding, which required expensive tooling and extended lead times. However, 3D printing offers an additive approach, building parts layer by layer, drastically reducing waste, cost, and production delays. This breakthrough has made plastic 3D printing a preferred choice for startups, entrepreneurs, and established industries looking to create unique, custom products.

One of the major reasons behind the rising popularity of plastic 3D printing lies in its accessibility and versatility. Businesses can now design complex parts with intricate geometries that would otherwise be impossible to produce using traditional manufacturing techniques. Furthermore, because plastic is widely available in a range of formulations—from durable ABS and nylon to flexible TPU—companies have the freedom to select the perfect material for their application. This combination of affordability, speed, and versatility makes plastic 3D printing an invaluable service for custom design projects.

Cost-Effective Customization with Plastic 3D Printing Service

One of the standout benefits of Plastic 3D Printing Service is cost-effective customization. Unlike injection molding, which demands the creation of expensive molds and tooling, 3D printing eliminates upfront costs. This means businesses and individuals can create small production runs or one-off prototypes without investing heavily in infrastructure. As a result, plastic 3D printing has become the go-to option for startups testing new concepts or companies seeking to innovate without risking large capital.

Additionally, plastic 3D printing minimizes material waste compared to traditional processes, where cutting, milling, and machining often discard excess raw material. Because the printer builds the object layer by layer, only the necessary amount of plastic is used, making it both eco-friendly and budget-conscious. This cost-efficient nature has opened doors for designers to experiment more freely with custom designs, knowing that they can create, iterate, and refine products without incurring excessive expenses.

Flexibility in Design and Rapid Prototyping

The design freedom enabled by Plastic 3D Printing Service is unparalleled in the manufacturing industry. Traditional methods often impose strict design limitations due to tooling constraints, but 3D printing allows creators to bring even the most complex ideas to life. Whether it’s intricate lattice structures, organic shapes, or components with hollow sections, plastic 3D printing can handle designs that are otherwise impossible to achieve with conventional manufacturing. This flexibility is crucial for industries such as automotive, healthcare, and consumer goods, where innovation drives competitiveness.

Equally important is the speed of prototyping offered by plastic 3D printing. In the past, developing a prototype could take weeks or even months. With 3D printing, designers can move from concept to physical prototype within days or even hours. This rapid prototyping capability accelerates product development cycles, enabling businesses to test, refine, and launch products much faster. For companies competing in fast-paced markets, the ability to quickly respond to consumer demand with custom solutions is a significant competitive advantage.

Material Variety and Application Diversity

Another major advantage of Plastic 3D Printing Service lies in the diverse range of materials available. From rigid thermoplastics like PLA and ABS to engineering-grade materials such as nylon and polycarbonate, plastic 3D printing supports a broad spectrum of applications. For example, PLA is often used for cost-effective, eco-friendly prototypes, while ABS offers durability and heat resistance for functional parts. Meanwhile, flexible TPU enables the production of elastic components, making it ideal for wearable devices, seals, and grips. This material diversity ensures that custom designs can meet both aesthetic and functional requirements.

The versatility of materials also extends the applications of plastic 3D printing across industries. In the medical field, custom prosthetics and surgical tools can be produced to match individual patient needs. In consumer markets, personalized products such as phone cases, jewelry, and household items are increasingly being manufactured with 3D printing. For industrial uses, lightweight yet strong plastic components are being created for automotive and aerospace applications. This ability to cater to both personal and industrial-scale demands highlights why plastic 3D printing is becoming an essential tool for customization.

Future Opportunities and Innovations in Plastic 3D Printing Service

The future of Plastic 3D Printing Service looks exceptionally promising as technology continues to evolve. Advances in printer hardware, software, and material science are pushing the boundaries of what is possible. High-speed 3D printers are emerging that can produce larger quantities without sacrificing quality, making them suitable for both prototyping and small-batch production. Additionally, innovations in recyclable and biodegradable plastics are aligning plastic 3D printing with sustainability goals, appealing to environmentally conscious businesses and consumers alike.