In modern manufacturing, businesses need innovative solutions that ensure both efficiency and precision. One of the most critical aspects of product development, especially in the automotive and industrial sectors, is the ability to create accurate prototypes before entering mass production. This is where prototype molding services come into play. By offering a quick and affordable way to validate product designs, they provide companies with the tools they need to minimize risks, optimize performance, and accelerate time-to-market.

As industries continue to advance with new materials, technologies, and designs, the demand for reliable prototype molding services has never been greater. Automotive companies rely on them to test new parts for durability and safety, while industrial manufacturers use them to validate functionality and design efficiency. This ability to create and test parts before committing to full-scale production ensures higher quality outcomes and reduced production costs.

The Importance of Prototype Molding in Automotive Development

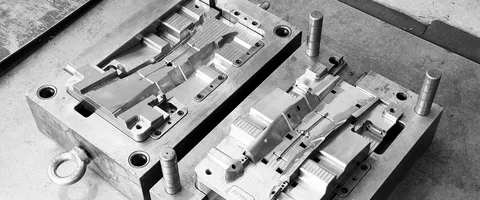

In the automotive sector, precision and reliability are critical factors that determine the overall safety and performance of vehicles. With cars becoming more advanced and technology-driven, every new part needs thorough testing before it can be mass-produced. Prototype molding services provide automakers with the ability to develop accurate replicas of components, ensuring that designs meet performance, safety, and aesthetic standards.

From dashboards and interior fittings to engine components and exterior parts, automotive companies use prototype molding to test different materials and designs. This not only helps in identifying flaws early in the development phase but also ensures compliance with stringent industry regulations. By leveraging prototype molding, automotive manufacturers can significantly reduce production delays, eliminate costly errors, and accelerate the launch of innovative vehicles.

Industrial Applications of Prototype Molding Services

In addition to the automotive sector, industrial manufacturers also heavily rely on prototype molding services. These industries often deal with heavy machinery, equipment, and specialized parts that must withstand extreme operating conditions. Prototyping allows them to test new product designs for structural integrity, durability, and functionality before committing to large-scale production.

Industries such as aerospace, energy, and construction benefit greatly from prototype molding, as it enables them to explore various material choices and design modifications. With the ability to create multiple iterations quickly, companies can compare results and choose the most efficient and cost-effective design. Ultimately, this process ensures reliability, reduces waste, and enhances overall productivity in industrial manufacturing.

Benefits of Using Prototype Molding Services

One of the key advantages of prototype molding services is the reduction of time and cost in product development. By creating prototypes, companies can identify design flaws early on, eliminating the risk of costly rework later in the production cycle. This streamlined process significantly reduces the time-to-market, giving businesses a competitive edge in fast-paced industries.

Additionally, prototype molding helps businesses maintain a high level of quality and consistency. By testing different materials, designs, and production techniques, companies can ensure that their final products perform reliably under real-world conditions. This not only increases customer satisfaction but also enhances brand reputation and fosters long-term business growth.

Choosing the Right Prototype Molding Partner

Selecting the right provider for prototype molding services is a crucial step in achieving successful product development. Companies should look for a service provider with expertise in both automotive and industrial applications, as well as a proven track record of delivering high-quality prototypes. Advanced equipment, skilled engineers, and experience with diverse materials are essential factors to consider when choosing a reliable partner.

Furthermore, the ability to offer customized solutions is critical. Every business has unique requirements, and a good prototype molding partner should be flexible enough to adapt to those needs. By working with a trusted service provider, businesses can ensure that their prototypes meet design specifications, comply with industry standards, and deliver consistent performance across all applications.

The Future of Prototype Molding Services in Manufacturing

As technology continues to evolve, the future of prototype molding services looks promising. Advancements in materials, 3D printing integration, and digital design tools are making it easier than ever to create precise prototypes in record time. This transformation is particularly beneficial for industries like automotive and industrial manufacturing, where innovation and speed are vital to success.

In the coming years, prototype molding is expected to become even more integral to product development, offering greater flexibility, reduced costs, and enhanced design accuracy. Companies that embrace these services will be better positioned to adapt to market changes, introduce innovative products, and maintain a competitive advantage in their industries.

Conclusion

Reliable prototype molding services are an essential part of modern automotive and industrial manufacturing. They provide businesses with the ability to test, refine, and perfect designs before mass production, ultimately saving time, money, and resources. By ensuring that every part meets industry standards for safety, performance, and quality, prototype molding helps manufacturers deliver innovative solutions that meet the demands of today’s market.